A form of ball valve where the ball is forced to move by pressure from gases or liquids is a ball check valve. The valve automatically closes when the fluid’s pressure on the ball ends. The seat is manufactured to fit the ball, while the chamber is formed conically to help the ball enter the seat to seal and stop a reverse flow. Lighter balls can be chosen if the pump’s capacity is insufficient, while heavier balls can be chosen if the water hammer occurs after the pump stops. Read More…

Our check valves are manufactured with the customer in mind. We believe in offering superior products and services every time. No matter whether you are looking for small or large valves, we can meet your every needs. It is our goal to offer excellent prices and service to each customer. Contact us to learn more today!

Our team at Control Devices believes that all of our customers should receive products that exceed their expecations. That’s why we design and produce our check valves using the highest quality materials. We will work with each customer to help find a lasting solution. Our company is ISO 9001:2015 certified. Contact Control Devices today to learn more!

We make our check valves to be wear resistant and able to withstand the elements in sewage, sludge and slurries plus hold up to pressure drop. Rubber and full-metal-body check valves are offered. Contact us about your process piping needs. EVR Products is an ISO 9001:2015-registered company.

Manufacturing standard or custom check valves, pressure relief valves, needle valves, control valves, pressure regulators and instrument-quality tube fittings plus other flow and pressure control products is our business. Generant is ISO 9001:2000 certified. We have been in business for 75+ years.

More Ball Check Valve Manufacturers

Design of Ball Check Valves

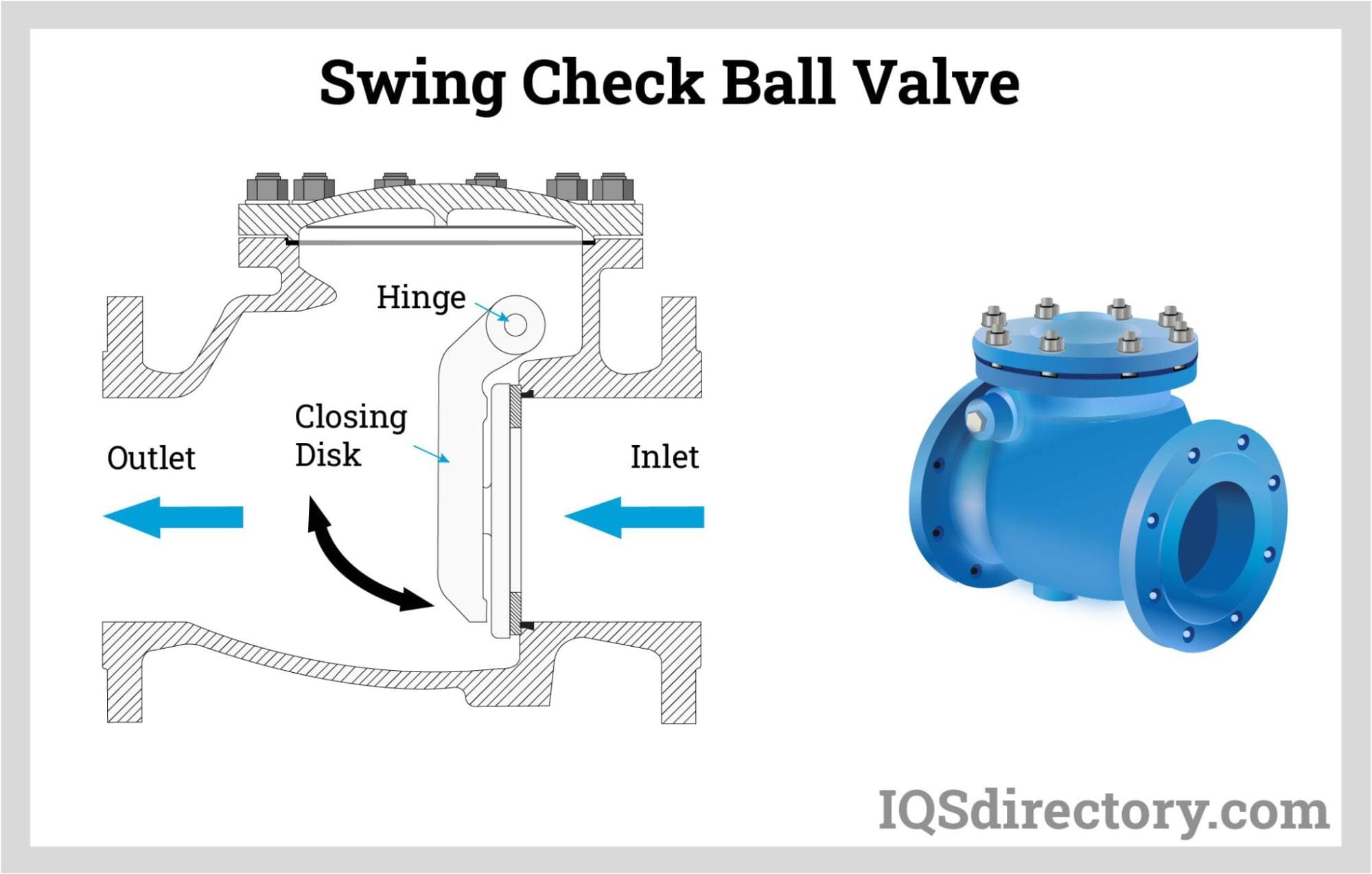

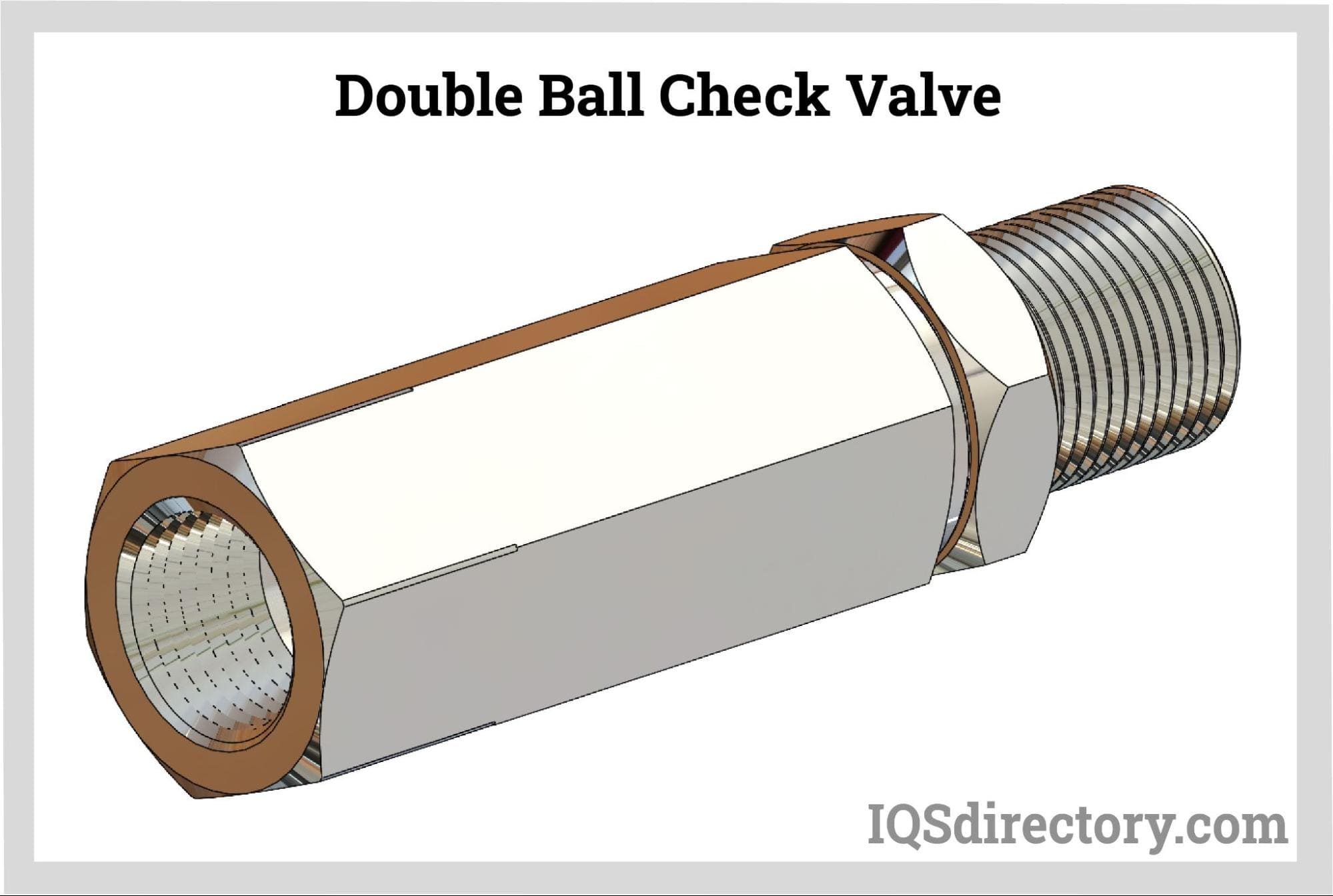

Two-port valves, such as ball check valves, have two apertures in the body—one for fluid entry and the other for fluid exit. Gravity and reverse liquid pressure are required to reseal every ball-style check valve. Four components make up a standard ball check valve: a body or pipe; a ball; a valve seat; and a specifically-made conical spring. The gases or liquids flowing through the body exert pressure, which causes the ball to rise.

By opposing the force generated by the rising ball, the conical spring balances the volume of the flowing liquid or gas. They are intended to stop water from running backward via the pipe system, sump pumps, and water heaters and are most frequently utilized in the plumbing sector. Brass or stainless steel are two materials that can be used to make ball check valves.

Considerations in Ball Check Valve Selection

Operating Conditions

When choosing the housing materials, it is important to consider the ambient heat generated by the valve during operation. When temperatures are high, brass is a great material for valve housing.

Life Expectancy (Upkeep)

To determine the necessary maintenance, consider the valve's expected average lifespan. Ball check valves of stainless steel have a high level of resistance to abrasion, pressure, and temperature.

Media

PVC ball check valves are a fantastic option if a gas or corrosive liquid is used as the operating medium. However, compared to valves constructed of brass and steel, these have lower pressure ratings.

Reduced Pressure

When choosing a ball check valve, it is critical to understand the pressure drop within the flow management system. The flow is controlled by variations in system pressure, which also affects how well the ball check valve works. When the downstream pressure exceeds the upstream pressure, the reverse pressure drop determines how tightly the valve closes off during backflow. A minimum pressure difference is required between a ball check valve's input and output ports. When selecting a valve, ensure it satisfies this demand and considers the required maximum pressure.

Control Method

A ball check valve allows fluid to flow forward but prevents it from flowing backward. The ball's weight, back pressure, a spring, or a combination of these mechanisms all work together to stop backflow. The ideal ball check valve should have no resistance to flow going forward and complete resistance to flow going backward.

Types of Ball Check Valve Connections

The following list of connection types applies to ball check valves:

- Flanged Ball Check Valves: Ball check valves with flanges on the inlet and outlet connections are known as flanged ball check valves. The flange is sized and drilled in compliance with specifications like EN 1092-2. Plumbing, firefighting, HVAC, and water/sewage treatment applications all require flanged ball check valves.

- Threaded Ball Check Valves: Threaded ball check valves contain internal or external threads for inlet or outlet connections.

- Soldered Ball Check Valves: These valves' ends are attached to the pipe fittings by soldering.

- Ball Check Valves as Compression Fittings: Ball check valves have a threaded or soldered-free sealed pipe connection.

- Ball Check Valves with a Buttweld Connection: Ball check valves with a buttweld connection for the inlet or outlet ports are known as buttweld ball check valves.

Uses of Ball Check Valves

- They’re found in systems for sprinklers and pipes.

- Backflow and the re-entry of possibly polluted water are both prevented by using ball check valves.

- Devices like liquid pump dispensers, sprayers, and dispensing syringes all use ball check valves.

- Ball check valves are used to force plastic forward during the injection molding process and prevent any from sliding backward.

Ball Check Valve Benefits

- Little size

- Simple to use

- Cheap

- They can be put in places where there is both vertical and horizontal flow.

- Ball check valves use a variety of media, such as gas, air, steam, vapor, or water, to handle high pressure and enormous fluid volumes.

- Self-cleaning of the valve is ensured by ball rotation.

- There are reusable seat rings.

Choosing the Right Ball Check Valve Supplier

To guarantee you have the best outcome when purchasing ball check valves from a ball check valve company, it is important to compare several manufacturers using our directory of ball check valve companies. Each ball check valve manufacturer has a business profile page that highlights their areas of expertise and capabilities along with a contact form to contact them directly for more information or to request a quote. Review each ball check valve business’ website using our patented website preview for a better understanding of what each business specializes in and, then, use our simple RFQ form to contact several ball check valve companies using the same form.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services