Valves are adaptable machinery used to regulate the flow of gasses or liquids. They are crucial components in various piping and industrial systems, working to control flow and pressure in order to avoid a system backflow. A spring check valve works to prevent backflow by using a spring to apply pressure on a disk that closes the valve when required. Read More…

Our check valves are manufactured with the customer in mind. We believe in offering superior products and services every time. No matter whether you are looking for small or large valves, we can meet your every needs. It is our goal to offer excellent prices and service to each customer. Contact us to learn more today!

Our team at Control Devices believes that all of our customers should receive products that exceed their expecations. That’s why we design and produce our check valves using the highest quality materials. We will work with each customer to help find a lasting solution. Our company is ISO 9001:2015 certified. Contact Control Devices today to learn more!

We make our check valves to be wear resistant and able to withstand the elements in sewage, sludge and slurries plus hold up to pressure drop. Rubber and full-metal-body check valves are offered. Contact us about your process piping needs. EVR Products is an ISO 9001:2015-registered company.

Manufacturing standard or custom check valves, pressure relief valves, needle valves, control valves, pressure regulators and instrument-quality tube fittings plus other flow and pressure control products is our business. Generant is ISO 9001:2000 certified. We have been in business for 75+ years.

More Spring Check Valve Manufacturers

A spring check valve is designed to guarantee one-way flow and prevent reverse flow. Spring check valves feature a single input and output. However, spring check valves must be positioned precisely to properly function. All check valves, including spring check valves, have an arrow on their side pointing in the direction of flow. Spring check valves are also referred to as on-return or one-way valves.

Types of Spring Check Valves

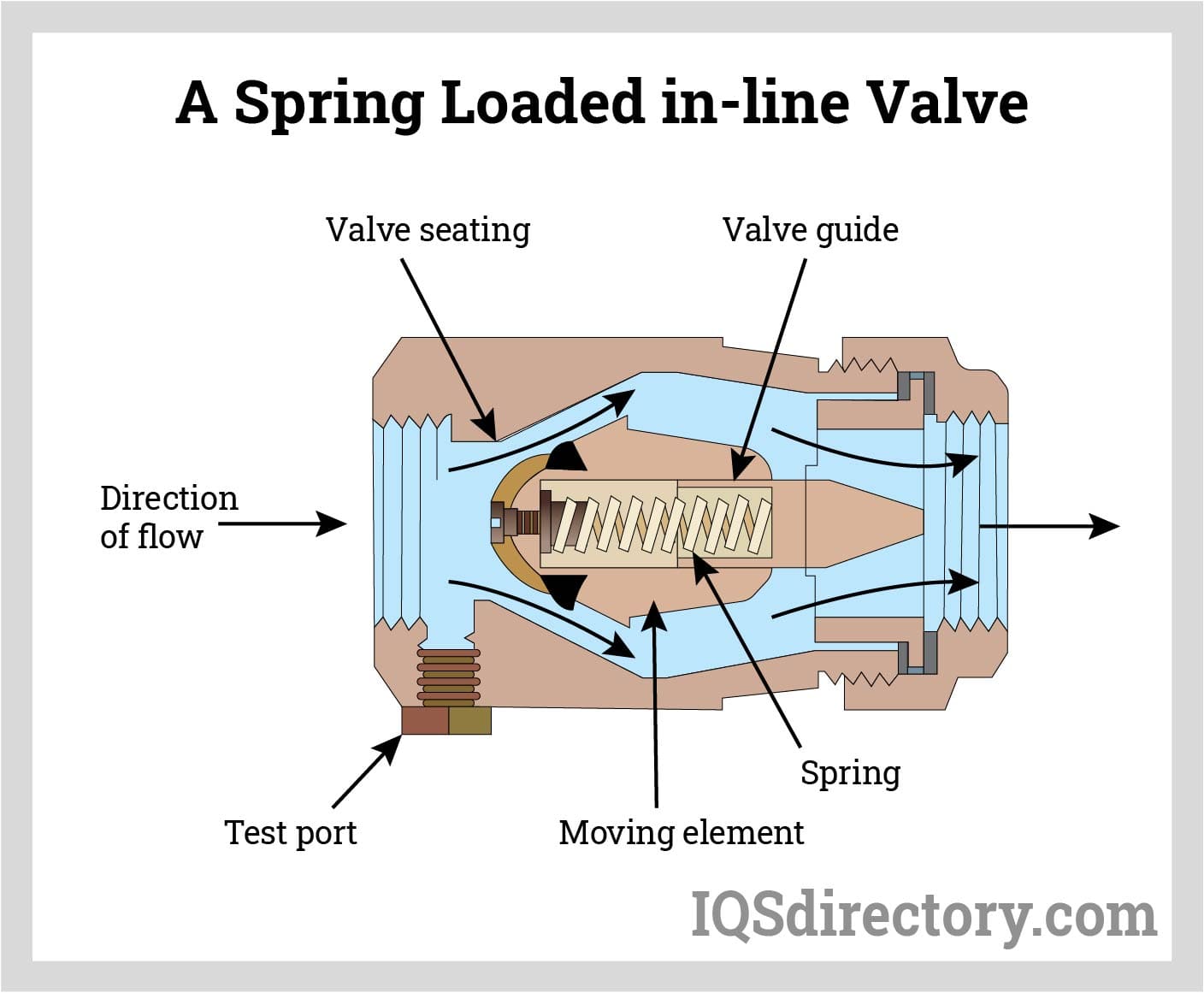

Spring-Loaded In-Line Valves

Spring-loaded in-line valves use a compression spring and a stem-disk assembly that is centrally directed. Flow pressure must be greater than the cracking pressure (the inlet pressure level when flow is originally detected) and spring force to open the valve. When this pressure is reached, the disk is pressed, enabling the flow. The valve subsequently closes when the input pressure drops because the spring forces the disk against the orifice.

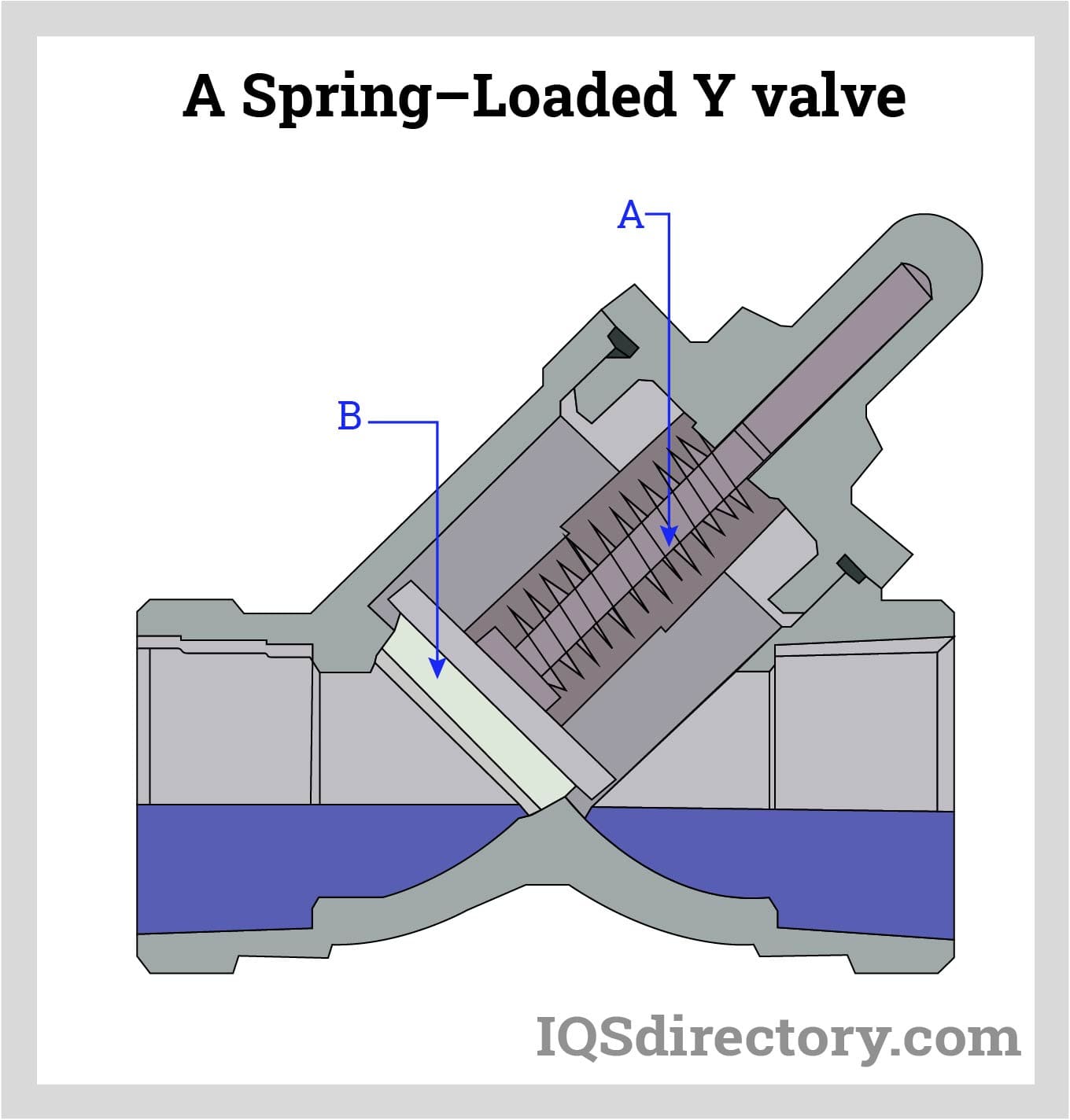

Spring-Loaded Y Valves

Spring-loaded y valves operate on the same principle as in-line check valves. Flow pressure determines when the valve opens and closes. The only difference is the spring (A) and rotational disk (B) are positioned at an inclination to create a “Y” shape. The principal benefit of this design is the ability it provides to be inspected and serviced while still plugged into the system.

Foot Check Valves

A foot check valve is also known as a ball checking valve since it features a ball which maintains or restricts flow. A foot check valve can maintain or allow flow solely in one direction by blocking the route in the opposite direction. These valves serve as mechanisms to stop gravity backflows. Foot check valves are installed at the bottom of the intake ports of several piping systems. A screen or filtration shield on the valve prevents extraneous objects and debris from entering the main line. Foot check valves have wider input holes than upstream pipes to reduce pressure losses. Foot check valves are frequently used with wells, ponds, swimming pools, intake pumps, sump pumps, and hydraulic and pneumatic pumps.

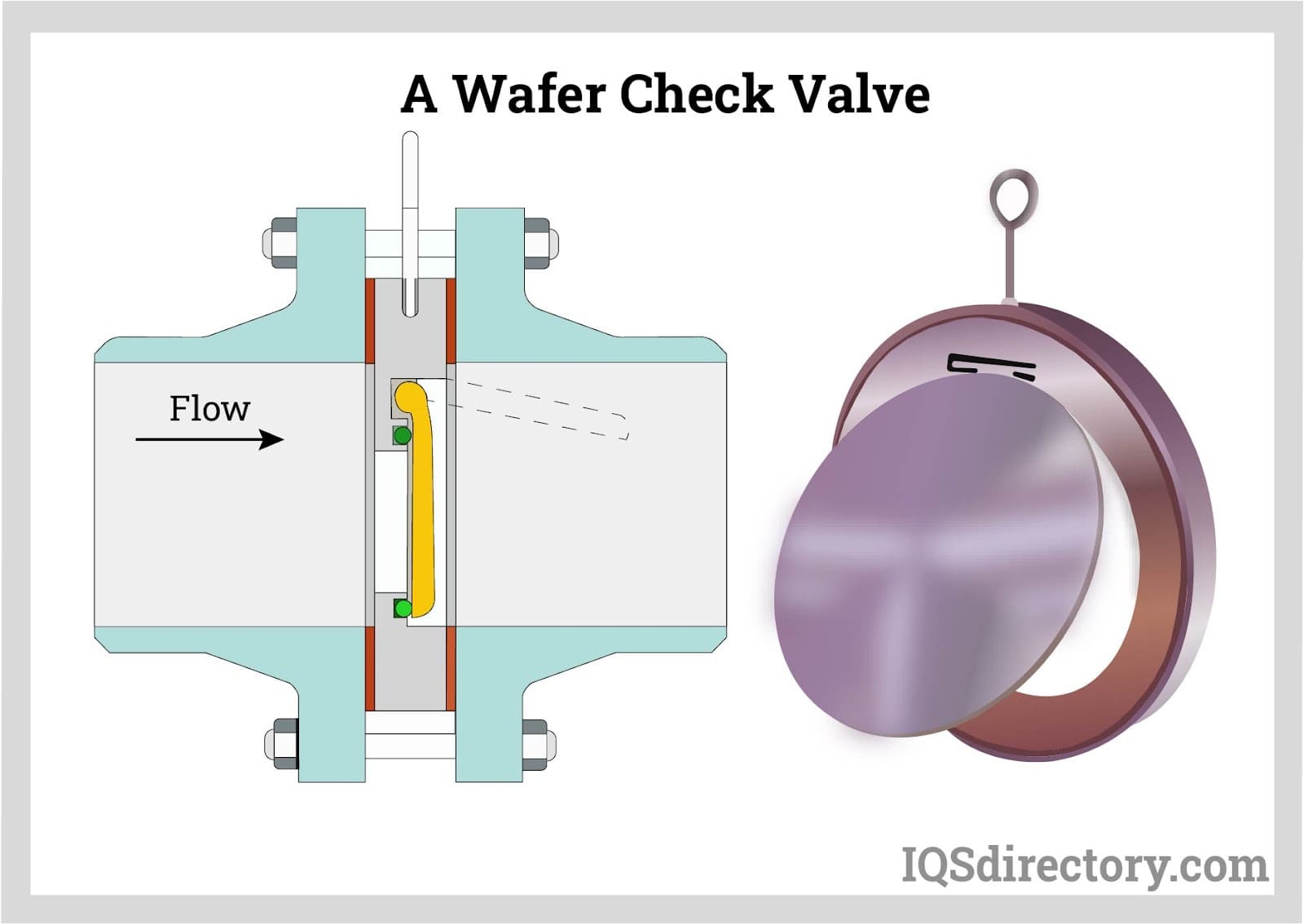

Wafer Check Valves

The two half-circle disks that make up a wafer check valve are hinged together. When there is positive flow, the twin disks fold together and retract completely to seal against reverse flow. Wafer control valves were created as a more compact, affordable alternative to lift and slide check valves. They're made to slide in between a pair of flanges. In wafer check valves, the spring is secured in position by a retainer and resists the disk's movement as it rotates in a plane at a right angle to the fluid flow. As a result, the disk rises off its seat and allows passage through the valve as the mainstream pressure rises and surpasses the pressure of the spring and the load of the disk. A wafer check valve can be fitted in any direction thanks to the spring. Since the action of the valve occurs at a very small pressure difference, wafer control valves are perfect for services needing low-pressure loss.

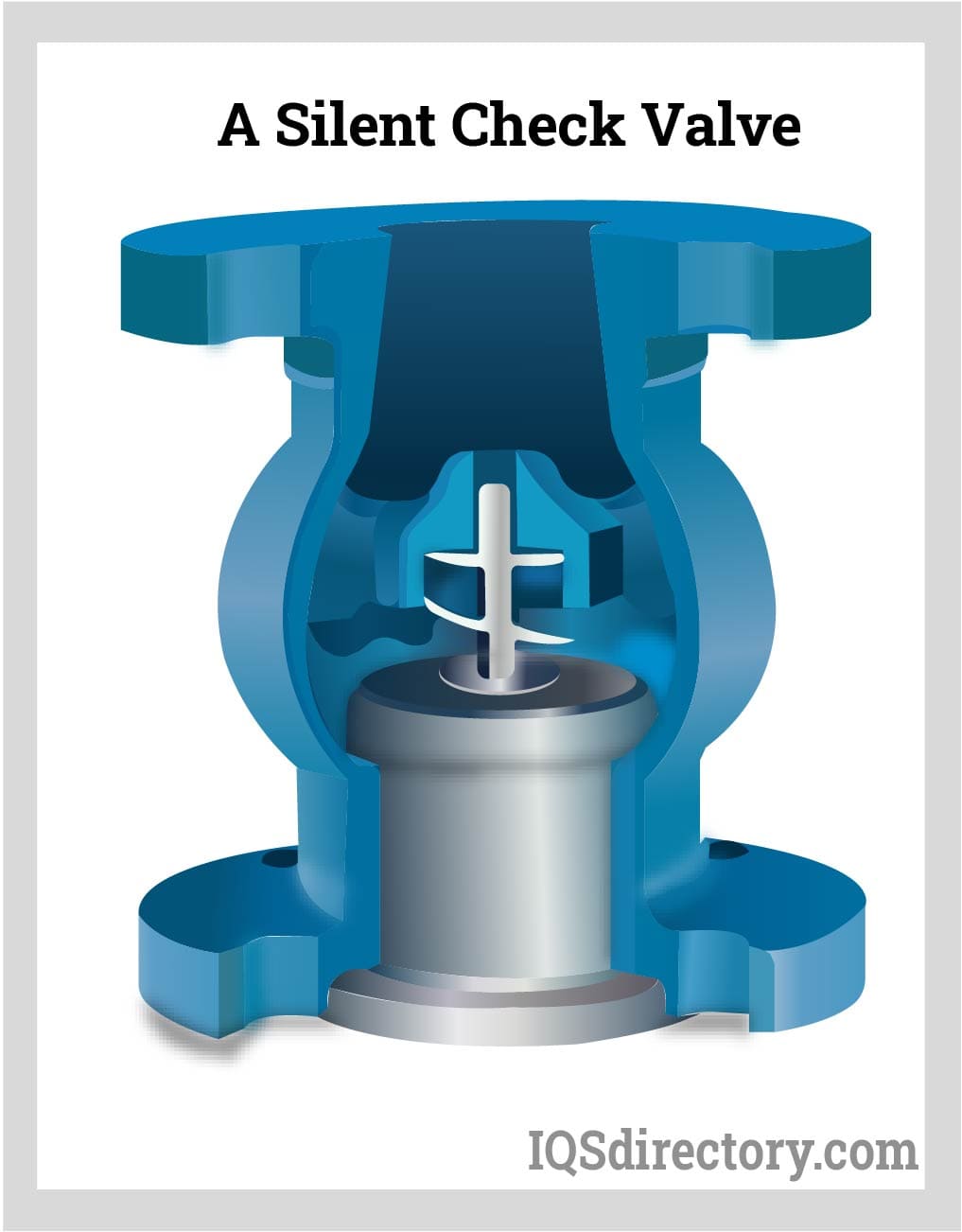

Silent Check Valves

Silent check valves, often known as poppet check valves, are renowned for closing quietly. Silent check valves have a spring-assisted disk in their design. This disk is pushed by the spring, enabling forward flow. The disk is pushed into the seats (or portion of an engine which the valve rests while operating) before flow reverses when the pump is shut and leads to the silent closure. Silent check valves were designed to regulate and safeguard against pressure spikes that can happen in water pipes. They also help to stop the reverse flow and water hammering (a pressure surge that can occur when fluid flow is abruptly changed or stopped). The majority of freshwater operations with high pressure employ silent check valves.

Connections

Spring check valves can be attached to a pipeline in several different ways. A good connection between both valves and pipes is essential for avoiding leaks. Connections can be made several ways, including through welding, flanges, threads, and soldered (or “sweat”) fittings. The various connection types guarantee a tight fit is available between the piping system and the spring check valve. Selecting the right connection method is crucial for the valves to work properly.

Conclusion

A spring check valve ensures unidirectional flow and avoids reverse flow. They have only one inlet and one exit and must be positioned correctly to work properly.

With spring check valves, the closing disc is held in place by a spring until enough pressure is exerted to cause the force to collapse and remove the disk from the pipe opening.

Selecting the Correct Spring Check Valve Company

For the most beneficial outcome when purchasing spring check valves from a spring check valve company, it is important to compare several spring check valve suppliers using our directory of spring check valve suppliers. Each spring check valve supplier has a business profile page that highlights their areas of expertise and capabilities, along with a contact form to directly contact them for more information or to request a quote. Review each spring check valve company using our proprietary website previewer to get an understanding of what each business specializes in. Then, use our simple RFQ form to contact multiple businesses with the same form.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services