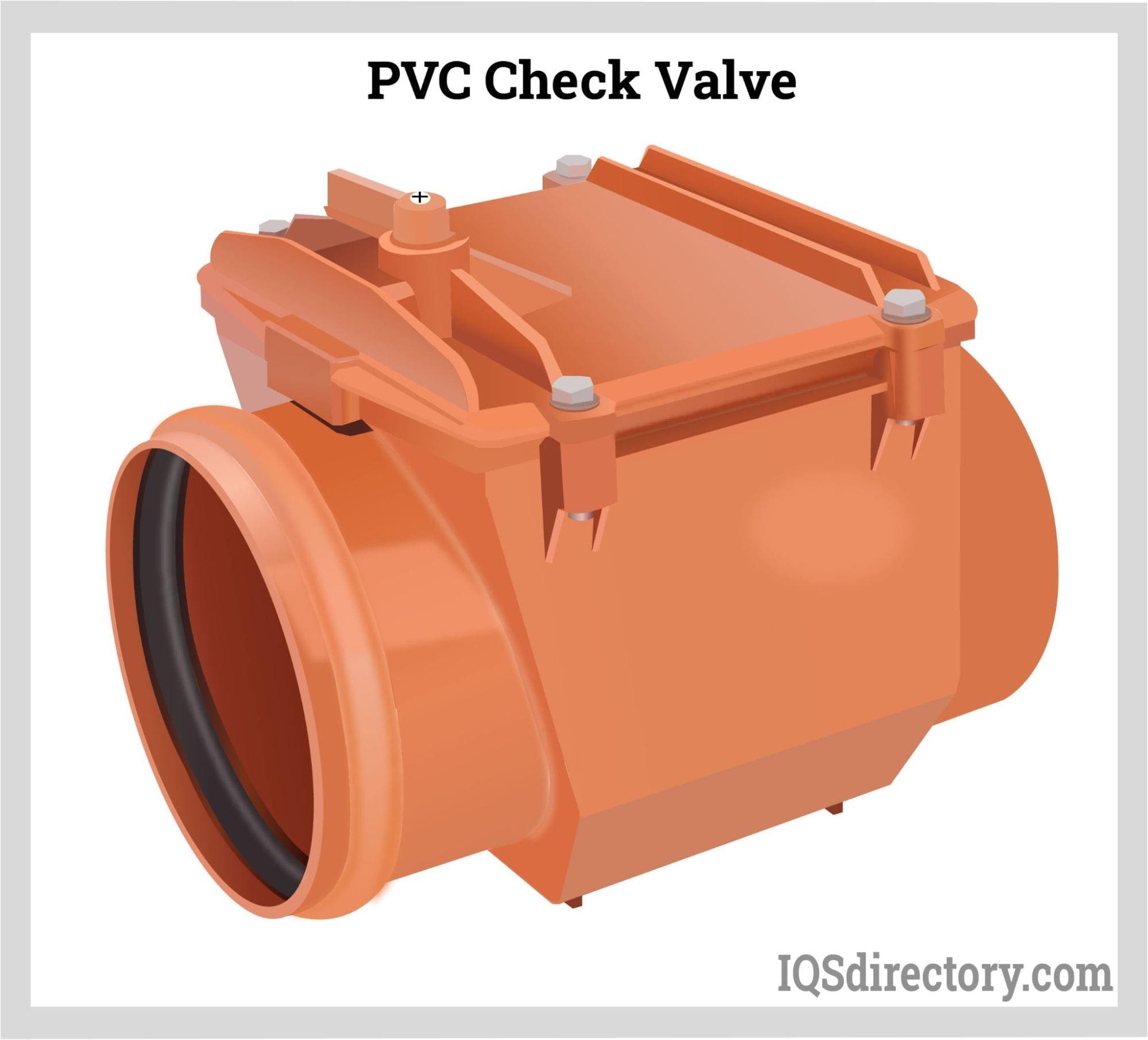

Plastic check valves come in various forms to regulate and guarantee the proper flow of fluids through a system. PVC check valves are just one of these forms. They ensure that liquid, gas, or slurry does not cause backflow and flows solely in one direction. Read More…

Our check valves are manufactured with the customer in mind. We believe in offering superior products and services every time. No matter whether you are looking for small or large valves, we can meet your every needs. It is our goal to offer excellent prices and service to each customer. Contact us to learn more today!

Our team at Control Devices believes that all of our customers should receive products that exceed their expecations. That’s why we design and produce our check valves using the highest quality materials. We will work with each customer to help find a lasting solution. Our company is ISO 9001:2015 certified. Contact Control Devices today to learn more!

We make our check valves to be wear resistant and able to withstand the elements in sewage, sludge and slurries plus hold up to pressure drop. Rubber and full-metal-body check valves are offered. Contact us about your process piping needs. EVR Products is an ISO 9001:2015-registered company.

Manufacturing standard or custom check valves, pressure relief valves, needle valves, control valves, pressure regulators and instrument-quality tube fittings plus other flow and pressure control products is our business. Generant is ISO 9001:2000 certified. We have been in business for 75+ years.

More PVC Check Valve Manufacturers

PVC non-return valves, PVC clack valves, and PVC non-return valves are other names for PVC check valves. In any case, the versatile thermoplastic polymer resin with the same name, PVC, also known by its full name, polyvinyl chloride, is used to make PVC check valves. PVC can be manufactured in various ways to better handle the numerous abrasive, acidic, or corrosive materials that may flow through a check valve. As a result, PVC check valves are used to control flow in a range of industrial, home, and commercial activities.

PVC Check Valve Designs

To create PVC, vinyl chloride monomers and water are typically suspended in a polymerization reaction. To provide the PVC with particular additional qualities, other compounds, including plasticizers, stabilizers, and lubricants, are frequently incorporated. A polymer can be made transparent or opaque, conductive or insulating, and flexible or rigid, for example, by adding substances. Manufacturers can select from various available procedures to convert PVC into check valves after it has been synthesized. These include die molding, extrusion, injection molding, and stamping. Most PVC check valves are made essentially the same. They have a stopper mechanism, an output port, and an inlet port. The valve is under pressure in the forward direction when fluid enters through the inlet port. The stopper mechanism, most likely a disk, ball, or piston, will then be able to move slightly due to a properly working valve. It will only open in one direction, and pressure from a flow from the opposite side will drive the stopper back into its hole to establish an airtight seal rather than opening it. The valve will only reopen when the forward pressure exceeds the back pressure. PVC check valves are extremely simple to integrate into an existing cistern or pipe because their operation is self-contained and doesn't require any external actuation or activation.

Types of Check Valves

PVC ball check valves, diaphragm check valves, swing check valves, and tilting disk valves are a few examples of PVC check valve subtypes. Ball check valves are check valves with a movable closing element, or component, that prevents fluid flow shaped like a ball. Some ball check valves have a spring-loaded mechanism that aids in keeping the ball in place. Without this mechanism, certain ball check valves are kept closed by a reverse flow that maintains the ball at the seat and seals it. Next, a flexible rubber diaphragm keeps a usually closed valve from opening. For the system to function, there must be an acceptable pressure differential, or a certain quantity, between the upstream and downstream pressures. The valve opens under high pressure and closes under low pressure. Check valves with a disk that swings on a trunnion or hinge are called swing check valves. The flow-blocking disk, or movable component, swings onto either the seat to prevent reverse flow or swings off the seat thereby allowing forward flow. The flapper valve attached to the toilet flush lever is a well-known illustration of this type of PVC check valve.

Advantages of Check Valves

For various reasons, PVC is used as the material for checking valves. Its smoothness, flexibility, and lack of toxicity are a few of these advantages. PVC also compresses and produces a very tight and reliable seal when used as the seal of both plastic and metal valves. PVC can also be easily produced into precise shapes. PVC check valves share many of the same qualities as metal check valves but at a far more affordable price. PVC is also more cost-effective and environmentally friendly than most other polymers because it uses a lot less petroleum in its production. The other advantages of check valves are:

- Able to withstand circumstances of both high and low pressure

- Able to be utilized both horizontally and vertically to serve as a backup and safety system

- Self-actuated

- Swift action

- Keep pumps and compressors safe from backflow damage

- Reduce production losses and downtime

- Avoid water hammer

- Lessen unexpected valve failure

- Lower costs for maintenance

- It has few moving parts

- Have reduced footprints

- Able to handle conditions of fluctuating flow

- Do not need electricity to function

Disadvantages of Check Valves

Reverse Flow:

Reverse flow is expensive and can harm a pump by spinning it counterclockwise. Check valves with tight fitting and quick shutting capabilities help solve this issue. The capacity of spring-assisted check valves to respond rapidly and prevent reverse flow is one of their advantages.

Chattering:

Chattering results from some check valve systems' continuous opening and closing. This repeated action is due to the oversized check valve. Before installation, a check valve must be sized to fit the application. In addition, the disk must be stable in the open position and create a perfect seal when closed to prevent repeated opening and shutting, flapping, and check valve failure.

Installation:

The incorrect assembly and installation of check valves may result in future problems. The first step is to choose the right check valve for the application. Considering flow capacity, placement, and direction is crucial since placing a check valve too close to a pump could cause turbidity and possible check valve breakage.

Choosing the Right PVC Check Valve Manufacturer

To ensure you have the most positive outcome when purchasing PVC check valves from a PVC check valve manufacturer, it is important to compare several companies using our list of PVC check valve companies. Each PVC check valve manufacturer has a business profile page illustrating their areas of expertise and capabilities, along with a contact form to communicate with them directly for more information or to request a quote. Review each PVC check valve manufacturer website using our patented website previewer to gain a better understanding of what each business specializes in. Then, use our simple RFQ form to contact multiple PVC check valve companies with the same form.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services